YO TANA MACHINE TOOLS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to YO TANA MACHINE TOOLS P.LTD.

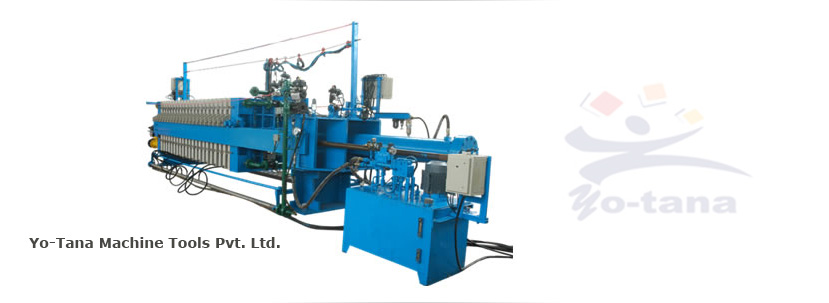

Membrane Filter Press

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart.

However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped.

At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber.

The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result.

Membrane filter plates are used to

Reduce filter cake moisture content

Reduce filtration cycle time

Improve cake washing

This style of filter plate can be installed as

A full plate pack

Alternately in conjunction with recessed companion plates as a more economical option.

Because of its simplicity and flexibility, the chamber Filter Press has been widely applied in clarification and dewatering applications. Membrane Filter Press technology is gaining increased acceptance because it reduces subsequent processing or disposal costs for filter cake. In many applications the membrane Filter Press significantly reduces residual moisture content, making this technology attractive for new plants and for upgrading existing facilities. In both cases the careful selection of plate and membrane materials is essential to the successful performance of the process.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.